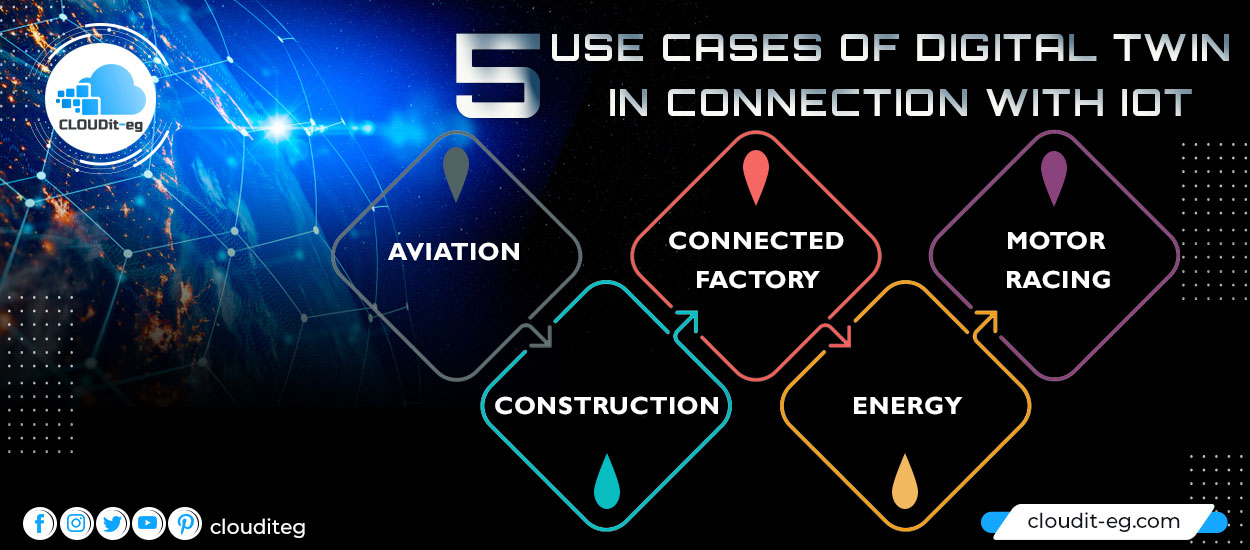

With IoT, the physical world and the virtual world come together. Discover 5 use cases of the digital twin in connection with IoT.

The digital twin or digital twin in English aims to create a digital double of a product, a building, a vehicle, in short, any object with connected sensors. It is a matter of making a virtual copy of the physical world in order to identify problems, to understand the functioning of a complex whole without even moving.

Analysis of the data collected in real-time from these sensors provides additional information in addition to a digital representation of the cabling, on-board systems, and the 3D model. Preventive and predictive maintenance, monitoring, simulation, visualization… The possibilities are numerous. However, many people still have difficulty identifying the possible uses of this technique.

Here are 5 use cases of the digital twin in connection with IoT;

1. Aviation: the digital twin saw by General Electric

Let’s start with the most popular sector for industrial design players: aviation. Aircraft design, manufacture, and maintenance are very expensive. Manufacturers and operators want to be able to reduce the bill by getting crucial information that will tell them in advance when to intervene on a device, which parts need to be changed, and when? The PTC software editor is notably capable of modeling a digital twin of an aircraft subsystem. But the one whose services are the most developed in the sector is none other than General Electric Aviation.

The manufacturer offers its latest aircraft engines in an as-a-service model. It does not sell the engines to airlines, they lease them as a complement to predictive maintenance services for these machines and a way to optimize flights while reducing ground time. The data are analyzed in real-time using machine learning and are made visible from a dashboard on which the engines are represented in 2D or 3D.

2. Construction: when the digital twin facilitates the management of connected buildings

Combining data from a PLM and data from IoT sensors seems more natural in the aviation sector than in the construction industry. Architects and site managers still work a lot on paper. However, digital solutions exist, in particular the BIM method, for Building Information Modeling. In French, it is translated by the expression modeling of building data. This involves combining architectural plans, information on the materials used, construction planning, budgets, and data from energy systems, IoT sensors placed in buildings. In short, a complete digital twin.

It is not only a question of carrying out simulations before construction but above all of optimizing the management of buildings and offices throughout their lifespan. Energy consumption, safety, accidents, predictive maintenance of the ventilation system or elevators, etc. Many elements can be integrated into a digital twin of a building. This is typically what Siemens undertakes by providing construction companies and maintenance managers with nearly 2000 sets of data, each corresponding to a particular product. Among these, are connected boiler room systems, electrical components, connected lamps, etc.

3. Connected Factory: virtual reality and IoT go hand in hand

Industry 4.0 brings together the technologies that will make the industry of tomorrow. Among these, the digital twin takes a good place. Aviation is surely the most advanced sector in the field. Real-time data visualization becomes essential in order to facilitate maintenance and optimize production. In this area, Altran is experimenting with Airbus with a virtual reality data visualization solution based on the VueForge IoT platform.

The digital twin represents the equipment of a parts manufacturing plant located in Cadiz, Spain. Operators can both learn to manage machines in a simulation mode or quickly see problems in the plant. With this model, it is possible to consult the production data remotely, outside the industrial site.

4. Energy: the digital twin, a security issue

We have above that the energy management of buildings can be done using a digital twin. Production can also benefit from this technique. Here again, simulation plays an important role since it involves managing industrial sites where safety is essential. By testing upstream, it is thus possible to predict the type of incidents that may occur, to plan interventions, and to better manage an event in a real situation. The big names in the energy sector quickly understood the value of connecting their infrastructures and viewing the data of their installations.

This is what EDF, the electricity production giant, decided to plan for in 2013. In this context, it is a matter of monitoring and managing the energy of nuclear power plants spread over all French territory. To do this, the company began by making digital twins for the various nuclear reactors. Beyond a production and safety issue, it is also a question of strengthening the cybersecurity of facilities by representing possible attacks from the digital twin.

5. Motor Racing: maximizing driver performance

In this last point, we enter the era of professional sport. If this is often entertaining, motor racing requires constant attention from the drivers, the organizers, and the staff involved in the various teams. This is particularly true in the main discipline: Formula 1. In this area, the McLaren team has taken a few laps in advance. It uses a digital twin of its single-seaters by reporting real-time data on the condition of the tires, engine, fins, and even brakes, all connected. The data is analyzed from the company’s headquarters in Woking, England, in order to advise pilots on the strategy to be taken based on the information inferred by the technical team. Here again, the fusion of the physical and the digital gives a strategic advantage to maximize the performance of the pilots. In this case, she brought in industry specialists, SAP.